|

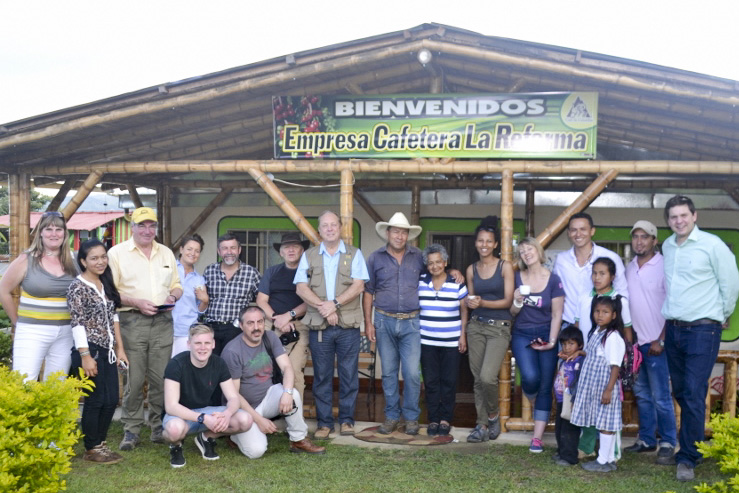

In early February Masteroast visited our Colombian suppliers. A number of customers and guests joined us on the trip to Southern Huila and Quindío. Part 1Part 2 Part 3 |

MasteroastA collection of articles written by the dedicated staff of Masteroast Archives

April 2022

Categories

All

|

Our ServicesCoffee SourcingDesign ServiceQuality Assurance |

|

|

Copyright © 2024, Masteroast Coffee Company Ltd, 01733 842000

|

|